Hot Rolled Steel Products

Hot rolling involves rolling the steel above its re-crystallization temperature (typically over 1700° F). At this temperature, it can be shaped and formed easily, and the steel can be made in much larger sizes. Post the milling process at high temperature, the steel cools off and shrinks slightly thus giving less control on the size and shape of the finished product when compared to cold rolled.

Grades

- E250, E350

- SAPH440

- FE-410

- IS 1079

HR - IS 2062

- SPFH590

- BSK46

- SPFH - STEEL PICKLED FULL HARD

- SAPH - STEEL ANNEALED PICKLED HARD

High Strength

Pickling And Oiling Treatment

- Hot rolled pickled and oiled sheet and coil have been descaled of an oxide film and oiled to help combat corrosion during storage and when in use. Hot rolled steel products will scale when in contact with oxygen and water vapor after the forming process. An acid bath removes scale that may form on the surface of hot rolled steel as it cools. After rinsing, dried oil is applied to the steel’s surface to prevent rust formation.

Applications For Hot Rolled Pickled & Oiled Steel Products

Applications that use hot rolled pickled and oiled steel products include

- Automotive

- Strapping

- Tubing

- Rack Systems

- Construction

- Lawn and Garden

- Various Stampings

- Thickness - 1.6 to 15mm

- Coil Weight - Minimum 400-500kg

- Coil Width - Upto 2000mm

.jpg)

- Thickness - 1.6 to 4mm

- Bundle Weight - Your desired quantity

- Sheet Dimensions - Flexible

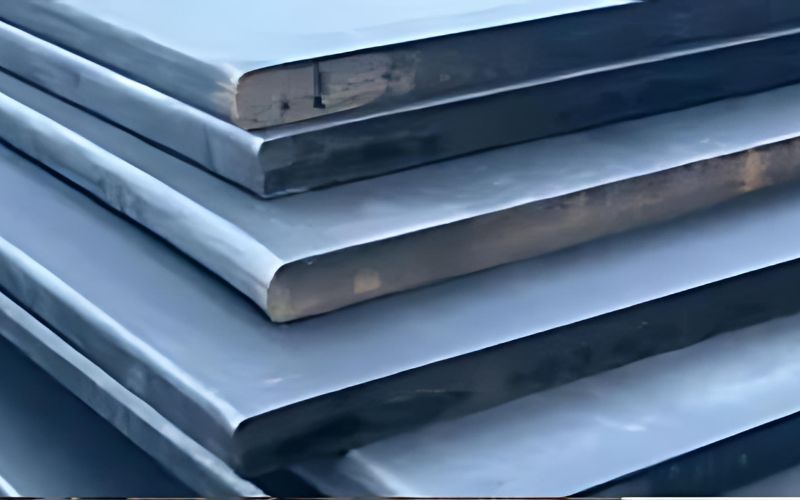

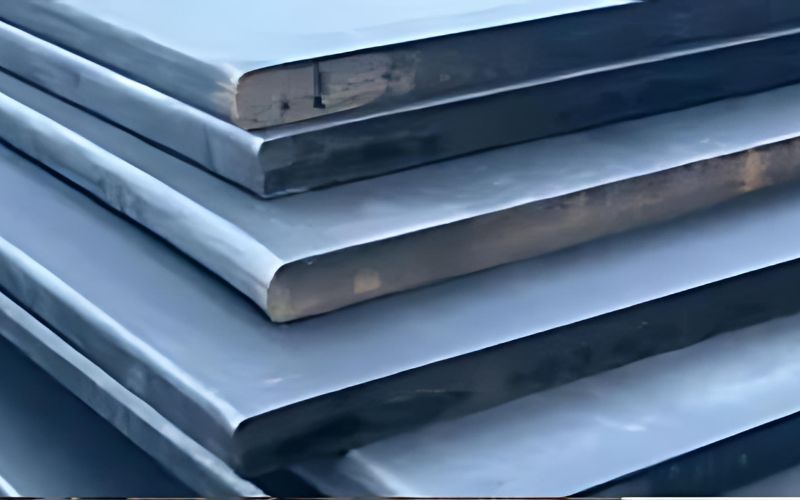

- PLATE is the technical and most common term used for HR sheets above 4mm.

- Thickness - Above 4mm

- Pickled and Oiled HR Coils

- Thickness - 1.6 to 10mm

- Coil Weight - Minimum 0.5MT

- Coil Width - Upto 2000mm

- Pickling of HR coils can also be done (Max 6mm Thickness)

- Pickled and Oiled HR Sheets

- Bundle Weight -Your desired quantity

- Bundle Dimensions - Flexible

- Pickled and Oiled HR Plates

- Similar to HR Plates, HRPO Plates are sheets above 4mm, with Pickling and Oiling surface treatment.

- Thickness - Above 4mm